Flexible PCB Manufacturers Provide Support

Printed circuit boards are crucial to the operation of electronic devices. However, these boards can be damaged during shipping and handling. If a flex PCB is damaged, it must be repaired as soon as possible to ensure the device remains functional. The question is, do flexible pcb manufacturer provide support for rework and repair? The answer is yes, but it’s important to know the types of repairs that can be made.

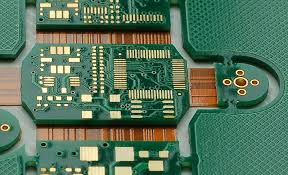

Flex PCBs are usually built on a polyimide (PI) base film. Unlike standard fiberglass and metal cores, this material is flexible after thermosetting. PI also resists humidity and tears, making it ideal for flex PCB construction. In addition, PI provides good electrical properties, despite being thin and lightweight.

To prevent corrosion and short circuits, a layer of copper is typically placed on top of the PI base. This layer also helps transmit signals to other parts of the board. A flex circuit manufacturer can add additional layers to increase the thickness of the board, but this may result in an increased cost. Additionally, a flex circuit maker can apply an anti-static film to the board. This film reduces electrostatic discharge and protects the copper from electromagnetic interference (EMI).

A flex PCB can be made with single, double, or multi-layer constructions. The design and fabrication process is similar to that of a rigid PCB. The main difference is that the flex circuit has a thinner substrate and requires a different assembly process.

Do Flexible PCB Manufacturers Provide Support for Rework and Repair?

When selecting a flex PCB manufacturer, look for one that offers an extensive range of manufacturing services for different applications. These companies have multiple factories and expert technicians to meet all your PCB-type needs. These include conventional, RF, HDI, and copper inlay PCBs. Moreover, they offer a variety of materials and fabrication processes, including immersion silver and gold and over-molding.

Most reputable flex PCB manufacturers follow strict standards and quality assurance programs. This means that they must comply with UL and ISO regulations. They must also have a wide range of production equipment, such as drilling tools, soldering stations, surface finishing devices, imaging equipment, and more. Lastly, they must use a streamlined manufacturing process to ensure the quality of their products.

Rework and repair of a flexible circuit board require advanced skills, materials, and tools. This is especially true when repairing fine traces and spaces on the PCB. Inexperienced repair attempts can exacerbate existing problems or introduce new ones. The repair process also requires access to accurate design documentation for the original flexible PCB.

Reliable flex PCB manufacturers will provide an extensive array of services to address any issues that may arise during the production process. For example, they will offer to do an electrical test for their customers’ circuit boards. This is an excellent way to make sure everything went right during the production phase and to catch any errors before the end of the production cycle. In addition, they will re-solder problem connections using industry-standard soldering techniques. If necessary, they can also re-laminate the faulty components or replace them with new ones.