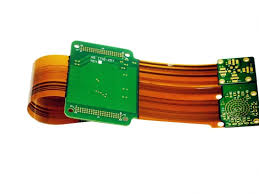

Proper Grounding in Flexible PCB Boards

When you are working with flex PCBs, you need to ensure the circuit’s grounding system is in good condition. This helps prevent electrostatic interference and reduce noise in the board. The ground plane provides a low-impedance path for electrical currents to return to the power source. Without it, currents may find alternate paths through the circuit and cause electromagnetic interference (EMI) and other problems.

One of the most important aspects of a flex PCB’s grounding is its design. You should make sure the ground plane is not located near power nets or components. It should also be able to handle the load and temperature of the circuit. This is possible by using a high-density layout and placing the ground plane on the bottom layer. You should also map out the traces and place them so that they do not create conductive rings that will cause electromagnetic interference.

Another way to help ensure proper grounding in a flexible pcb board is by utilizing via stitching. This is done by adding short traces between the power and ground planes. This will help reduce the voltage drop across the traces and avoid any interference. Another way to prevent EMI is by making the ground plane as large as possible. It should cover the entire bottom layer, as this will help to keep currents low and prevent EMI from occurring.

How to Ensure Proper Grounding in Flexible PCB Boards

The best way to ensure proper grounding in a flex circuit is by connecting all plated mounting holes to the on-board GND net/plane. This will ensure that the GND voltage is at the same potential as the chassis-ground connection, and it will prevent noise in the circuit.

In addition to connecting all the plated mounting holes, you should also connect the GND pins of connectors and components to their respective ground areas. This will help to keep the ground voltages at the same level and prevent a ground loop.

A ground loop is a conductive ring of metal that can conduct an electric current and generate interference. It can occur when different ground points on a circuit have different voltages. To help avoid ground loops, you should use bypass capacitors on each RF signal pathway. These can be placed close to the RF signal’s power supply pin to help prevent EMI from occurring.

Rigid-flex PCBs offer a number of benefits, including their durability and streamlined installation process. They also have a more flexible structure that allows them to undergo thousands of flex cycles. This enables them to withstand the stresses of the device’s environment, such as vibration and bending. In addition, rigid-flex circuits have a lower cost than traditional PCBs.

To ensure that the flex circuits you manufacture are free of defects, it is important to follow design rules carefully. These rules include proper grounding, as they can reduce the chances of open and short testing during production. In addition to this, you should also use a conductive coating on the mounting hole to protect against static charge buildup.